Non-Woven Fusible Interlinings: The Backbone of Modern Garment Construction

Non-woven fusible interlinings are true workhorses in garment construction. They give clothes the structure, shape, and stability needed to look polished. These “behind-the-seams” essentials hugely impact the final feel and look of any clothing item. From delicate blouses to sturdy coats, interlinings are widely used across all apparel types.

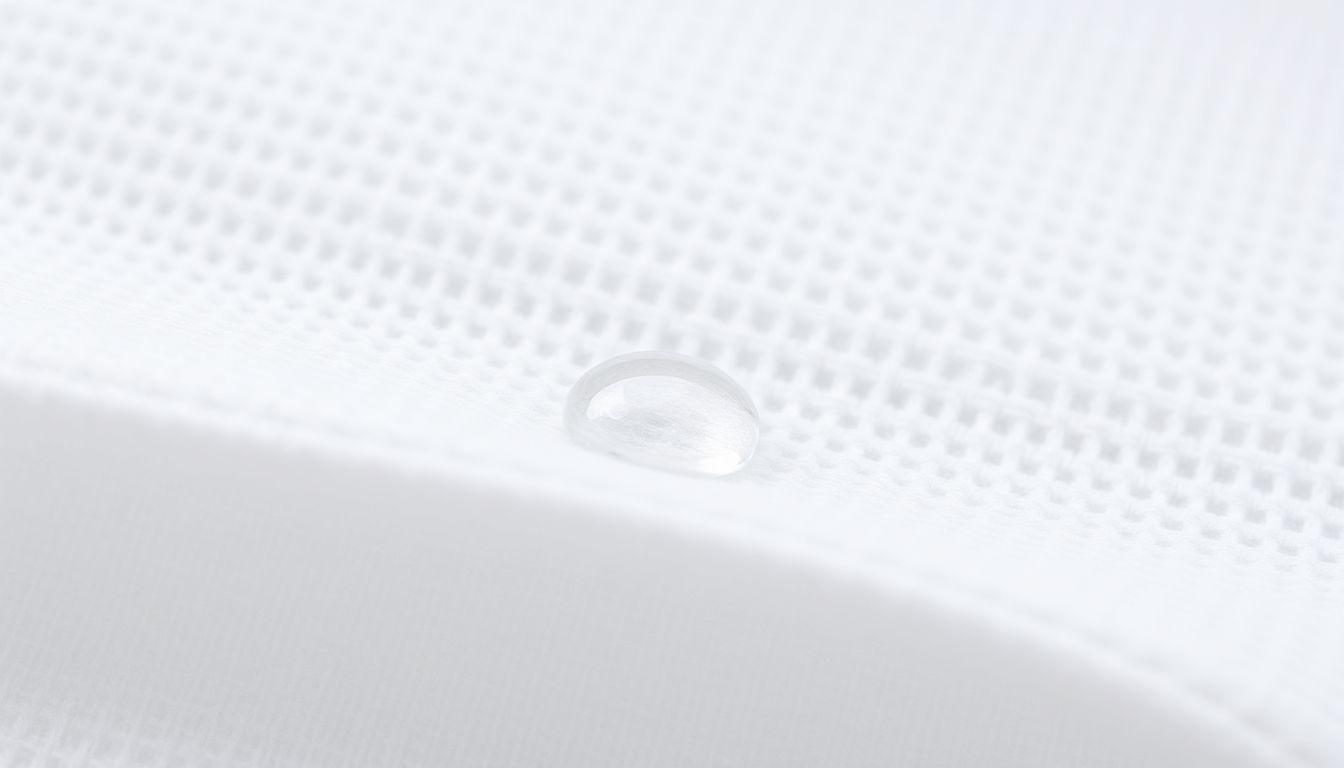

“Non-woven” simply means the fibers are bonded without weaving. Think of it like a dense mat where fibers are joined mechanically, chemically, or with heat. “Fusible” means these materials have a special thermoplastic adhesive. This glue melts when you apply heat and pressure, then bonds firmly to your main fabric.

Interlinings have come a long way, becoming vital for modern apparel making. They help create everything from sharp suit lapels to flowing dress bodices. Understanding their types, uses, and how to pick the best one is key for any serious sewer.

Understanding Non-Woven Fusible Interlinings

What are Non-Woven Fusible Interlinings?

Manufacturing Process

These interlinings are made through several cool methods. Air-laid processes use air to form a web of fibers. Hydro-entangled methods use high-pressure water jets to tangle fibers together. Needle-punched techniques use barbed needles to mechanically interlock the fibers. Each process creates a fabric with unique weight, drape, and strength.

Learn more about our non-woven fabrics and how they are manufactured

The Fusible Adhesive

The real magic is in the adhesive. Interlinings feature tiny dots or a full coating of hot melt adhesive. This can be a powder coating or specific resins. The adhesive’s melting point and how it’s spread affect the bond’s strength. It also changes how the interlining acts during the fusing process.

Key Properties and Characteristics

Weight and Thickness

Weight, often measured in grams per square meter (gsm), and thickness are vital. They help you match the interlining to your main fabric. Lightweight interlinings, around 20-40 gsm, suit delicate fabrics like silk. Medium-weight options, 40-80 gsm, are perfect for cotton or linen. Heavyweight interlinings, over 80 gsm, work well for wool or denim.

Drape and Hand Feel

Interlinings significantly alter how a garment hangs. Some offer a crisp, almost paper-like feel, great for structured collars. Others provide a soft, supple touch, keeping the fabric flowing naturally. Consider if you want to add body without stiffness, or firm up a weak fabric.

Stretch and Recovery

Modern fabrics often have stretch. So, your interlining needs to keep up. Some interlinings offer 2-way stretch, moving with the fabric across its width. Others provide 4-way stretch, offering give in all directions. This is crucial for knits and stretch wovens to prevent a stiff, rigid feel.

At Sadiq Interlinings, we produce interlinings that balance these properties for both delicate and heavy fabrics.

Types of Non-Woven Fusible Interlinings and Their Applications

Lightweight Interlinings

Sheer and Delicate Fabrics

Lightweight interlinings are perfect for delicate fabrics. Think silk, chiffon, organza, or fine cotton. These interlinings are almost transparent. They add structure without bulk, keeping your fine fabric looking airy. They prevent stretching or fraying on fragile edges.

Collars and Cuffs on Blouses

You want crisp collars and cuffs on blouses, but not stiff ones. Lightweight yet firm interlinings achieve this balance. They provide just enough support. This keeps your blouse looking neat without taking away from its overall soft drape.

Medium-Weight Interlinings

Suit Jackets and Trousers

Medium-weight interlinings are essential for tailored items. They stabilize suit jacket lapels, pocket welts, and trouser waistbands. These options give good body and keep the garment’s shape over time. They are the backbone of a well-made suit.

Dresses and Skirts

Give bodices, waistbands, and hemlines of dresses and skirts extra oomph with medium-weight interlinings. They help create a flattering silhouette. Your seams will lie flat, and your garment will hold its intended form beautifully.

Heavyweight Interlinings

Coats and Outerwear

For robust items like coats and outerwear, heavyweight interlinings are necessary. They stabilize heavy wools, tweeds, and denims. These interlinings add significant structure and durability. They ensure your coat maintains its shape through many seasons.

Bags and Accessories

Structured bags and hats need serious reinforcement. Heavyweight interlinings are ideal here. They provide the rigidity required for these items. They prevent collapsing and help accessories hold their shape perfectly.

Choosing the Right Non-Woven Fusible Interlining

Fabric Compatibility: The Golden Rule

Matching Weight and Fiber Content

Matching the interlining’s weight to your main fabric is critical. For lightweight cotton, a 20-30 gsm interlining is good. A medium wool might need 50-70 gsm. Heavy tweed could use 80+ gsm. Always try to match the interlining’s fiber content to your main fabric. This prevents issues like different shrinkage rates after washing.

For professional garment manufacturing, explore our fusible interlining solutions.

Understanding Fabric Drape and Stretch

Before choosing, examine your fabric. Does it drape softly or stand stiff? Does it stretch a lot or hold firm? Pick an interlining that works with these qualities, not against them. If your fabric stretches, use a fusible with matching stretch. This ensures the finished garment moves naturally.

Fusing Considerations

Testing Adhesive Performance

Always pre-test a small piece of interlining on a fabric scrap. This is your bond test. Apply heat, pressure, and time as recommended. After it cools, peel it back slowly. You want a strong bond, no adhesive showing through (strike-through), and no shine on the fabric. A good bond will resist peeling.

Ironing vs. Fusing Press

A household iron can work, but a professional fusing press offers consistent heat and pressure. For an iron, use a pressing cloth and small, overlapping movements. Never slide the iron, as this can distort the fabric. Apply firm, even pressure to each section. This avoids uneven bonding and weak spots.

Best Practices for Applying Non-Woven Fusible Interlinings

Preparation and Layout

Pre-shrinking and Testing

Pre-shrinking your interlining is a must. If it shrinks differently from your main fabric, you will get puckers. Always pre-wash your main fabric too, if it’s washable. Remember to test your fusing settings on a scrap first. This saves time and fabric down the line.

Grainline and Placement

While non-wovens lack a traditional grainline like woven fabrics, some do have a direction with more stability. Pay attention to any instructions. Always place the interlining on the wrong side of your fashion fabric. Make sure it lines up perfectly before fusing.

Fusing Techniques

Achieving an Even Bond

Apply consistent heat and pressure for the recommended time. Too little heat or pressure means a weak bond. Moving your iron too fast will also lead to poor adhesion. Hold the iron still for several seconds in each spot. Overlap your presses slightly for full coverage.

Troubleshooting Common Issues

- Peeling edges: This often means not enough heat, pressure, or time. Re-press the area with more care.

- Strike-through: If adhesive shows on the right side, your heat was too high. Or, the interlining might be too heavy for the fabric.

- Shine or scorching: This also means too much heat. Always use a pressing cloth.

- Stiffening where not desired: The interlining is too heavy, or it’s not the right type for your fabric’s drape.

The Impact of Quality Interlinings on Garment Longevity and Aesthetics

Durability and Wearability

Preventing Stretching and Sagging

Interlinings are like invisible scaffolding. They reinforce stress points in a garment. This stops things from stretching out or sagging over time. Your garment keeps its shape, even with frequent wear. This means your carefully sewn items last longer.

Maintaining Structure Through Washing

Well-applied fusible interlinings help clothes handle washing. They prevent distortion and keep the garment’s form. This is a big advantage over some sew-in interlinings. Your clothes will look great even after many trips to the laundry.

Professional Finish and Appearance

Crisp Edges and Clean Seams

Interlinings create that high-end, polished look. They give you sharp lapels, neat hems, and stable seams. This enhances the overall polish of your garment. It makes every piece look expensive and well-made.

Expert Endorsement

“The difference between a home-sewn garment and a professional one often lies in the unseen details, and the interlining is paramount among them,” says Sarah Jenkins, a master tailor. She understands how vital these hidden components are.

This is why global brands trust Sadiq Interlinings Pvt Ltd. for consistent quality.

Conclusion: Elevate Your Sewing with the Right Interlining

Non-woven fusible interlinings are simply essential for professional garment results. They provide the structure, stability, and shape that makes a garment look truly finished.

Careful selection is key to your success. Always pick an interlining that matches your fabric type, desired drape, and fusing properties. This choice makes all the difference.

Proper application techniques, like pre-testing and consistent fusing, ensure a durable and beautiful finish. Don’t skip these vital steps.

Ready to see a big change in your projects? Start experimenting with different types of interlinings. Prioritize their use in your future sewing. You’ll definitely notice a significant improvement in your finished garments.

If you’re looking for premium non-woven fusible interlinings in Pakistan and worldwide, explore our product range today.